Can you imagine life without bread? For Slovenian company Gostol-Gopan d.o.o. Nova Gorica, bread means more than just food – it is the core of the business.

Can you imagine life without bread? For Slovenian company Gostol-Gopan d.o.o. Nova Gorica, bread means more than just food – it is the core of the business.

— FRIDAY, 06 FEBRUARY 2015 BY DANFOSS POWER ELECTRONICS A/S

Gostol-Gopan is an original equipment manufacturer (OEM) for industrial bakery solutions, established in 1947. Throughout the world, baking lines produced in Gostol-Gopan are actively baking a wide variety of breads and other bakery products every day.

Gostol-Gopan delivers complete baking lines and individual bakery equipment to their customers, for a wide range of baking processes: dough preparation, dough dividing, dough moulding, fermentation, bread baking and bread cooling. Energy efficiency is the key focus in line development. Its new generation of tunnel baking ovens, comprising types TPN, TPN_S and TPN_GP, is the result of this process.

Tunnel cyclothermic ovens are universal ovens used for continuous baking of all types of bread and cakes. Transport through the baking area are executed by means of a knitted steel mesh (TPN), granite plates (TPN_GP) and hinge blade (TPN_S). The heating medium used is oil, gas or combination of these two.

It operates as an independent unit or within automated lines. Main advantages are:

Extremely low consumption of energy needed for baking. For freely-baked bread also below

200 kWh/t of bread.

Significant heat energy savings achieved via

Insulation to reduce heat loss, including high-quality insulated return part and glazed windows state of the art burners

automatic regulation of conveyor traction in the baking zone

Potential additional energy savings, including

automatic vapor flow

compatible recuperators for flue gases and vapor

Electrical energy savings via the optimization of heating valves

A frequency converter-driven centrifugal fan for flue gases. The frequency converter ensures better power transmission efficiency and, above all, essentially reduces maintenance needs and prolongs the oven lifetime.

Direct drive with planetary reduction gear

Independent temperature regulation in the baking area.

Technological vapor is brought into the baking area. The quantity of vapor is regulated by means of manual valves or the automatic regulation of vapor flow.

| Application | Motor | Frequency converter | |||

| No. | Type | No. | VLT® Automation Drive | Options | |

| Fan | 2 | 11 kW asyn-chronous motor | 2 | 11 kW | VLT® PROFIBUS DP V1 MCA 101 VLT® 24 V DC Supply MCB 107 |

| Fan | 3 | 3 kW asyn-chronous motor | 3 | 3 kW | VLT® PROFIBUS DP V1 MCA 101 VLT® 24 V DC Supply MCB 107 |

| Conveyor | 2 | 1.5 kW asyn-chronous motor | 2 | 2.2 kW | VLT® PROFIBUS DP V1 MCA 101 VLT® 24 V DC Supply MCB 107 |

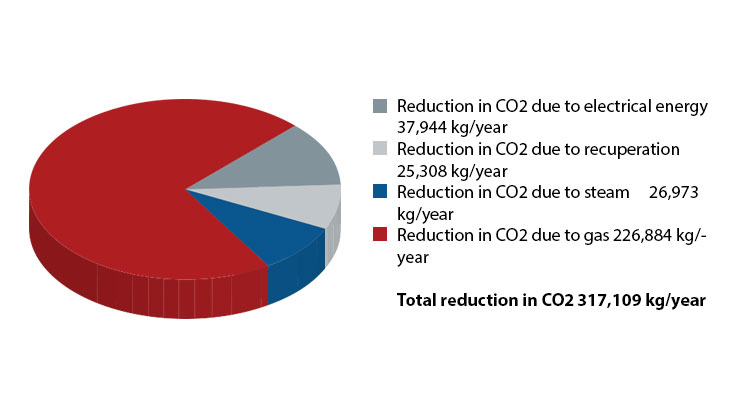

Heat and electricity energy savings give the cyclothermic oven a significantly reduced CO2 footprint, compared to a traditional oven.

The graph shows reduction of CO2 footprint in total, when using a Gostol cyclotermic tunnel baking oven type TPN to bake bread or other products, by comparison with an older traditional oven.

The graph data is based on these baking conditions:

Cyclothermic tunnel baking oven 3.75 m wide and 30 m long

Long loaf, weight 500 g

Production 24 hours/day, 300 days/year

Gas price 0.04 EUR/kWh

Electricity price 0.05 EUR/kWh

Gostol’s equipment enables adjustable baking time and temperature, which is the key reason for well baked, soft bread with a nice crust color. Baking time ranges from 10 to 90 minutes, dependent on the oven length, which can be from 12 to 60 meters.

The VLT® AutomationDrive FC 302 regulates the speed of the steel mesh conveyor, which determines baking time. The baking temperature can be up to 300°C. A centrifugal fan delivers heat from burners to radiators, located above and below the steel mesh. The system for forced air circulation in the baking hearth enables more intensive transmission of heat to the product. This system has roughly the same function as a fan in a domestic oven.y’s largest and produces 700.000 hl beer per year, using a mix of traditional techniques and cutting edge technology.

All these fans are regulated with VLT® AutomationDrive frequency converters, to reduce electricity consumption. The basic principle of saving is: hot air has lower density and needs less transmission force. By using a frequency converter to decrease the speed of a fan by 20%, the energy consumption is halved.

BIRRA FORST SpA was founded in 1857. In 1863 ownership was transferred to Josef Fuchs to become a family dynasty where the fourth generation continues to ensure the quality drinking experience made famous the by original brewers.

The brewery is one of Italy’s largest and produces 700.000 hl beer per year, using a mix of traditional techniques and cutting edge technology.

Automation Department Manager Mr. Srečko Lukan explains: “We started to look for suitable equipment with certification for the US market. Among other companies, we also contacted the Danfoss sales office in Slovenia for the right configuration of frequency converters. And this is the real value of Danfoss. The recommendation was VLT® AutomationDrive FC 302. This is the same VLT we have been working with for years. The only difference was the supply voltage: 3 x 208 VAC, 60 Hz. This saved us many working hours and a lot of effort – during design work, installation and start-up.”

One of the key benefits Danfoss offers to the customer is global service support. Danfoss provides a global service network in more than 100 countries.

Purchasing Department Manager Mrs. Irena Šinigoj sees advantages in Danfoss’ global service support: "Gostol-Gopan d.o.o. Nova Gorica is an export-oriented company. Some of our baking lines operate more than a thousand miles away from us. During a service case we are faced with many challenges. We work professionally with our customers, to ensure the core objective - that the line starts up again without prolonged downtime. It’s a good feeling, and adds value for our customers and ourselves too, knowing that Danfoss 24/7 service support can help us with service cases abroad. Downtime and costs for organizing service visits can be dramatically reduced. When required, we use the support offered by Danfoss. Hopefully we will not need it often."