In 2009, Unilever’s research on the efficiency of the existing boiler-house showed that a 25% reduction in CO2 emissions could be achieved by taking an innovative approach to renovate the boiler-house.

In 2009, Unilever’s research on the efficiency of the existing boiler-house showed that a 25% reduction in CO2 emissions could be achieved by taking an innovative approach to renovate the boiler-house.

— THURSDAY, 31 JULY 2014 BY DANFOSS POWER ELECTRONICS A/S

Unilever in Rotterdam is one of the largest margarine factories in the world producing more than 200,000 tonnes per year, along with the famous Calvé brand products. The processes are energy intensive and require heat (steam and hot water), compressed air and refrigeration, all taking huge amounts of electrical energy. A boiler-house provides much of the energy needs of the plant and in 2009, Unilever’s research on the efficiency of the existing boiler-house showed that a 25% reduction in CO2 emissions could be achieved by taking an innovative approach to renovate the boiler-house. Project E-mission was released in early 2010 and completed in September. The new boiler-house has been in operation for several months now.

Today, 1.6 MW of electric power and 2 MW of thermal power are generated by means of a Caterpillar combined heat and power (CHP) plant. The heat is used to provide the factory’s 90oC process heat supply although there is still a need for a boiler to produce 6.5 tons of steam per hour at 12 bar for many of the production processes. Three intelligently controlled air compressors were provisioned, with a total installed capacity of 500 kW.

Six refrigeration compressors have also been installed and the waste heat from these is recovered via a heat-pump adapted to supply the building’s central heating and the hot water system.

Hellebrekers Technieken designed and installed a complete new supervisory ViSpro SCADA system for the control, monitoring and operation of the whole boiler-house.

As well as the usual functions provided by such a system, Hellebrekers wrote custom-designed ‘energy pages’ to monitor and log energy usage. At a glance, energy values can be compared with values from a preceding period or with the same period from the previous year. This can be actively controlled to reduce energy consumption and CO2 emissions even more.

Clear control, excellent reliability and proven technology using Danfoss VLT ® AQUA Drive.

Clear control, excellent reliability and proven technology using Danfoss VLT ® AQUA Drive.

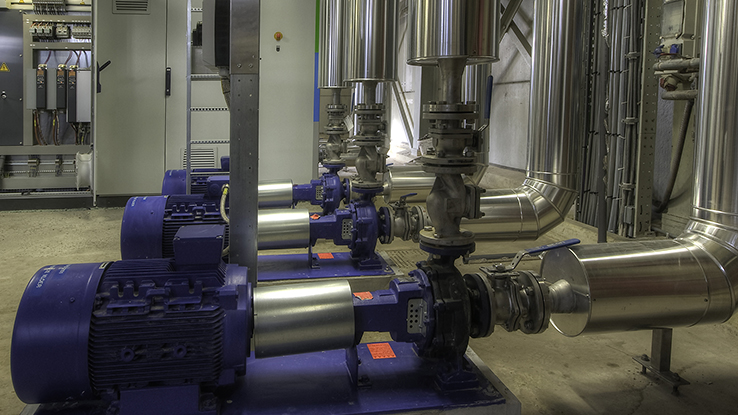

Hot water is used to distribute the heat generated. Water is heated to different levels in the boiler room and stored in buffers and double or triple centrifugal pump-sets pump the water around. .

There were three main considerations for the pump system:

1) The system had to be designed so the whole system would not fail as a result of the failure of a single system component.

2) Energy conservation was the prime reason for the boiler-house renovation so pump efficiency had to be maximised.

3) It should be possible to carry out maintenance on the system without shutting down the processes.

A Danfoss VLT® AQUA Drive with an VLT® Extended Cascade Controller MCO 101 was selected for efficient control of the pumps. An external 24V supply ensures that if the 400V mains fail, control circuits will remain powered-up and Profibus communication is selected to allow the SCADA system to monitor all data within the system.

The choice of a decentralised system offers numerous advantages. It permits certain sub-processes to work independently and only the data necessary for other processes are made available for import and export.

The entire process can be divided into smaller sub-processes and is made much easier. If you also choose an already fully developed system to control all the standard functions available, it saves considerable time on software development, engineering and debugging.

water. The pumps are pressure controlled via a pressure transmitter connected directly to the cascade control system installed in one of the inverters. The cascade control ensures the correct pressure. The Unilever installation has two- and three-pump configurations but the proven Danfoss pump cascade control can be extended up to eight pumps.

The three pumps in this system are sized to meet 150% of the calculated capacity so that full capacity is achieved with two pumps running. However, to ensure reliability, a 50% reserve has been provided so that should one of the three pumps fail, 100% capacity is maintained.

With the built-in intelligence of the cascade system, the operating hours of the three pumps are evenly distributed. Based on a change in capacity or to a built-in calendar, the controller will set individual pumps as ‘master’ or ‘follower’, thus sharing the running hours and wear evenly over the three pumps.

During operation, the operator can take a pump off-line simply by switching it off. The pump control system will identify this by the pressure drop and automatically switch to another pump.

All process data such as measured pressure, set-point, flow, operating hours, etc. is passed via the Profibus to the SCADA system where it can be used for control and monitoring purposes.

The Danfoss VLT® AQUA Drive provides a number of internal software features to ensure that energy savings are optimised. The built-in flow compensation ensures that adjustments are made even for small pressure reductions. For example, operation at 3 bar pressure might be fine, but 2.8 bar might be equally acceptable but more economical and this is independently controlled.

Using the VLT® Software Tool MCT10 set-up software made it extremely easy to commission the drives with the customer’s preferred values. The installation was up and running within one hour and after a few minor adjustments during the following week, control was optimized.