Danfoss AC drives are built for reliability. With IP 65/66 ingress protection, the drives are well-protected against demanding service conditions and cleaning processes which enhances system reliability. Built-in oil return management returns oil to the crankcase which also significantly improves system reliability. The functionality can be automatically activated in different ways under various demanding situations.

Dedicated compressor functionalities ensure capacity reduction while sustaining refrigeration system operation before the head pressure reaches a critical value. This maximizes system uptime and ensures food safety. Food safety and process continuity can also be safeguarded as the drive provides continuous compressor operation even during momentary power cuts.

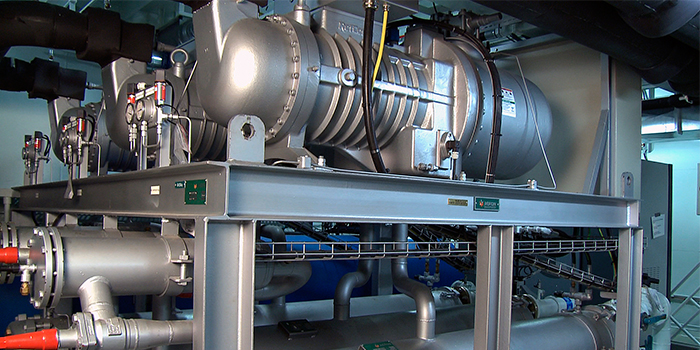

The smart logic controller allows intelligent capacity control of multi-piston compressors or screw compressors to deliver an improved COP.

The floating condensing temperature capability of the VLT® Refrigeration Drive optimizes COP by automatically lowering condensing temperature and raising evaporator temperature according to fluctuations in ambient temperature and product load. This functionality optimizes refrigeration system performance by increasing cooling capacity with lower power consumption. It also ensures the ability to run fewer compressors and reduce wear and tear.

Danfoss AC drives enhance atmosphere control by reducing evaporator fan speed according to the process needs. This saves energy, reduces losses and enhances the dependable storage of perishables such as fruits, vegetables and meat products.

Four built-in PID controllers with individual feedbacks and set points eliminate the need for an external controller. They allow closed-loop control of three external devices, such as dampers, valves and other peripherals, apart from the closed-loop control of the evaporator fan motor connected to the drive. This optimizes applied costs.

Danfoss AC drives handle logical rules and inputs from sensors, real-time functionality and time-related actions. This enables the drive to control a wide range of functions, for example weekend and working-day operations, cascaded P-PI for temperature control and belt monitoring.

Automatic Energy Optimization (AEO) provides additional energy savings of up to 5%. This feature matches the input current to the actual motor speed and load, and draws only the amount of power necessary for motor excitation and operation with this load. This avoids additional thermal losses in the motor.

With efficiency ratings up to 99% and a true power factor greater than 0.9, Danfoss AC drives are distinctly better than comparable devices. Losses for chokes and filters are already allowed for in the rating. This reduces not only direct energy costs for the drive itself, but also the costs for refrigeration or the removal of additional heat.

Continuous water or glycol supply can be assured in the event of leakage or a broken pipe. For example, overload is prevented by reducing drive speed and supply is secured at lower flow.

Dry Pump Protection and End of Curve features relate to situations where the pump runs without creating the desired pressure – for example, when a pipe leaks. In this situation the drive sets off an alarm, shuts off the pump, or performs another pre-programmed action.

Significant energy savings and reduced installation costs are provided by flow compensation in both fan and pump systems. A pressure sensor mounted close to the fan or pump provides a reference enabling pressure to be kept constant at the discharge end of the system. The drive constantly adjusts the pressure reference to follow the system curve.

An operating pump will normally consume more power the faster it runs according to a curve determined by the pump and application design. The No/low flow feature detects situations where the pump is running fast but is not fully loaded. This could indicate that water circulation has stopped, the pump has run dry, or a pipe is leaking. Continuous liquid supply can be assured in the event of leakage or a broken pipe. For example, overload is prevented by reducing drive speed – and supply is secured at lower flow.

Automatic Energy Optimization (AEO) provides additional energy savings of up to 5%. This feature matches the input current to the actual motor speed and load, and draws only the amount of power necessary for motor excitation and operation with this load. This avoids additional thermal losses in the motor.

With efficiency ratings up to 99% and a true power factor greater than 0.9, Danfoss AC drives are distinctly better than comparable devices. Losses for chokes and filters are already allowed for in the rating. This reduces not only direct energy costs for the drive itself, but also the costs for refrigeration or the removal of additional heat.