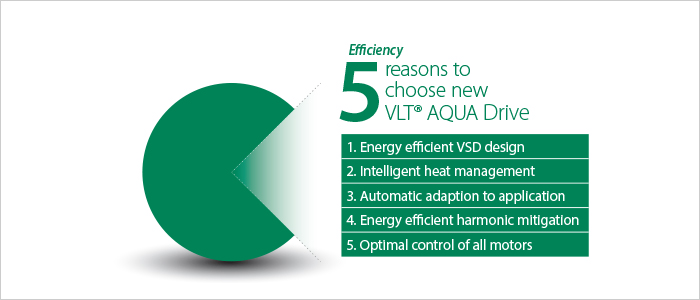

Our tight focus on energy efficiency at every stage of development, including the net efficiency when the new generation VLT® AQUA Drive is installed, means that you get a drive that delivers cost savings of up to 25% of the investment in the drive in its first year, when compared to traditional AC-drive solutions. That’s the equivalent to the savings gained by choosing an IE 3 motor instead of an IE 2.

1. Energy-efficient design

1. Energy-efficient design

The new generation VLT AQUA Drive’s control algorithm and design focuses on reducing heat loss, to maximize energy efficiency. Components are never loaded to more than 80% of their capacity. This reduces heat loss and increases efficiency.

2. Intelligent heat managementA unique back channel cooling concept transfers up to 90% of heat away from the room. This results in large energy savings on unnecessary air conditioning.

3. Automatic adaption to applicationAround 90% of all motors are oversized by more than 10%. AEO functionality can deliver energy savings of around 2% at 90% load, with typical savings of up to 5% over the whole range.

4. Energy-efficient harmonic mitigationOur unique VLT® Low Harmonic Drive with integrated AAF filter delivers an energy efficiency that is 1–2% better than a traditional AC drive with Active Front End technology. The Sleep function at low load secures further energy savings.

5. Optimal control of all motorsThe VLT® AQUA Drive’s capability to efficiently operate the different motor types in the market, secures you a free choice between motor suppliers. One of the latest developments is for high-speed PM motors. The unique Danfoss VVC+ control technology is ideal for high-speed turbo blowers using PM motors, offering from 0.5 to 3% additional installed energy savings compared with using traditional AC drives.

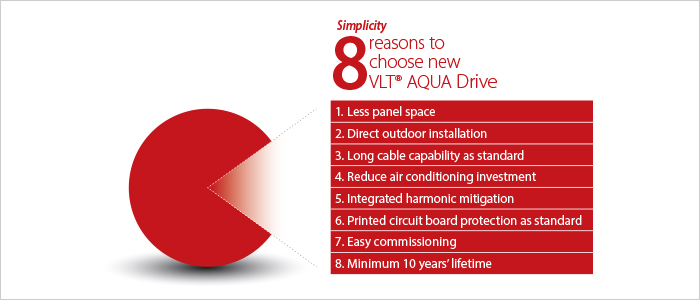

Based on our lengthy experience with the first ever dedicated water and wastewater drive on the market, the new generation VLT AQUA Drive offers very efficient installation and commissioning solutions which, compared to traditional AC drives, offer cost savings of between 10-20%.

1. Less panel space

1. Less panel space

The unique combination of Danfoss VLT® Low Harmonic Drive with integrated AAF filters, the ability to install the new generation VLT AQUA Drive side by side and its compact design offer a very space-friendly package when the complete solution is installed.

2. Direct outdoor installationAs standard, Danfoss offers AC drives in IP66/NEMA 4X. In addition to the convenience of having the drive close to the pump, this typically reduces cable costs, removes the need for air-conditioning capacity and lowers control room costs.

3. Long cable capability as standardWithout the need for additional components, the VLT® AQUA Drive provides troublefree operation with cable lengths up to 150 m screened and 300 m unscreened.

4. Air conditioning investment reduced by 90%The unique Danfoss back channel cooling system offers up to a 90% reduction in investment for air-cooling systems to remove heat from the AC drives.

5. Integrated harmonic mitigationThe VLT AQUA Drive is delivered with integrated harmonic mitigation solutions to a THDi level of 40% as standard. This saves space and costs while making installation easier.

6. Printed circuit boards protection as standardFrom 90 kW, the VLT AQUA Drive comes as standard with 3C3 PCB coating to ensure long lifetime even in harsh wastewater environments.

7. Easy commissioningWhether it’s a 0.25 kW or 2 MW drive you get the same control panel in your local language, the new SmartStart function and many other time-saving features.

8. Designed for a minimum 10 years’ lifetimeWith the VLT AQUA Drive’s high-quality components, maximum 80% load on components and intelligent heat management reducing dust on PCBs, the need for routine scheduled parts replacements, such as electrolytic capacitors and fans, has been removed.

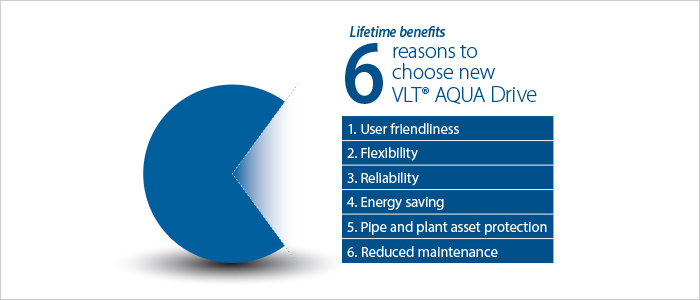

Danfoss Drives was the first to introduce a dedicated AC drive just for the water industry. All the application knowhow being built up over the years has been integrated into the new VLT AQUA Drive and provides many lifetime benefits.

The VLT AQUA Drive is the perfect match for water and wastewater applications. It is easy to use, flexible and reliable. For all operation conditions, from commissioning to stopping, specially designed software features help protect your assets. These features include avoiding water hammer, reducing maintenance on pumps and blowers and saving additional energy compared with traditional AC drive controls.

The VLT AQUA Drive gives your rotating equipment the best possible lifetime, with the lowest energy consumption and maintenance costs.