Earthing vs Grounding

Introduction

Earthing and grounding are two fundamental concepts in electrical systems that ensure safety and system stability. Although they are often used interchangeably, they have distinct purposes, applications, and technical differences. Understanding these differences is essential for engineers, electricians, and anyone involved in electrical system design and maintenance.

Definition

Earthing

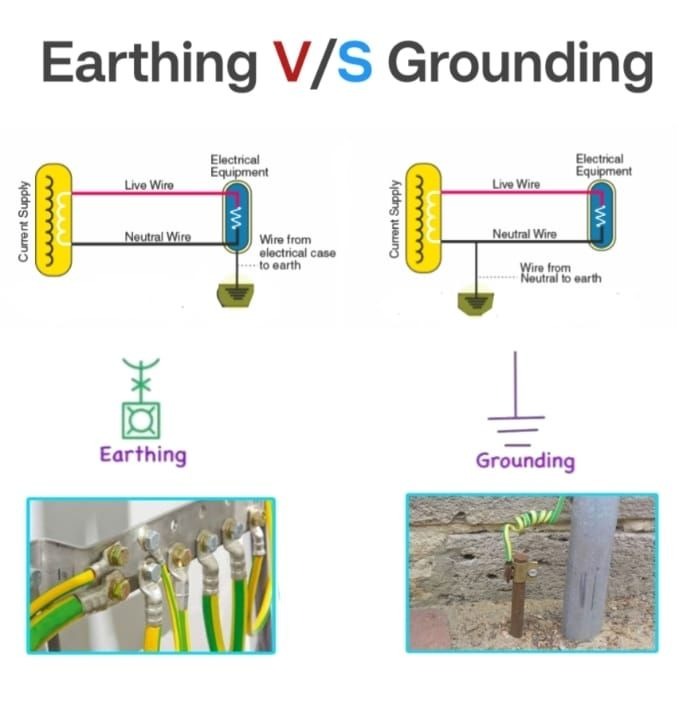

Earthing, also known as grounding in some contexts, refers to the process of connecting the non-current-carrying parts of electrical equipment to the earth. This connection ensures that the metal casing or enclosure of electrical devices remains at the same potential as the earth, providing a safe path for fault currents to dissipate. The primary purpose of earthing is to prevent electrical shock hazards by ensuring that in case of insulation failure or accidental contact with live parts, the excess current is safely discharged into the ground.

Grounding

Grounding, on the other hand, refers to connecting the current-carrying parts of an electrical system, such as the neutral point of transformers and generators, to the ground. This connection helps in maintaining system voltage stability and provides a return path for fault currents. Grounding is essential for balancing unbalanced loads, preventing overvoltages, and enhancing the safety of electrical installations.

Key Differences Between Earthing and Grounding

1. Location

- Earthing: The connection is made between the equipment body and an earth pit, which is typically a deep electrode buried underground.

- Grounding: The connection is made between the neutral point of an electrical system and the ground, ensuring a stable return path for current.

2. Wire Color Code

- Earthing: The standard wire color for earthing is green.

- Grounding: The wire used for grounding is generally black.

3. Types of Earthing and Grounding

Types of Earthing:

- Pipe Earthing: A galvanized steel or copper pipe is buried vertically in the ground and connected to the electrical system.

- Plate Earthing: A copper or galvanized iron plate is buried in the ground and connected via conductors.

- Rod Earthing: A copper or galvanized iron rod is used to create the earth connection.

- Tap Earthing: Used for industrial applications, where multiple earthing points are connected through conductors.

- Strip Earthing: A strip electrode (copper or galvanized iron) is laid in a trench to provide an effective earth connection.

Types of Grounding:

- Solid Grounding: The neutral is directly connected to the ground without any resistance.

- Resistance Grounding: A resistor is placed between the neutral and the ground to limit fault currents.

- Reactance Grounding: An inductor is placed between the neutral and the ground to control fault current magnitudes.

4. Potential Difference

- Earthing: The potential of an earthed component is always at zero potential, ensuring it is safe to touch.

- Grounding: The grounded component has a non-zero potential, as it is part of the electrical circuit.

5. Primary Use

- Earthing: The main purpose of earthing is to prevent electrical shocks by directing stray currents safely into the ground.

- Grounding: Grounding ensures voltage stability and helps balance unbalanced loads in the electrical system.

6. Examples of Usage

- Earthing:

- Transformer enclosures

- Generator casings

- Motor body protection

- Grounding:

- Neutral point of generators

- Power transformer grounding

- Substation grounding systems

Importance of Earthing and Grounding

Both earthing and grounding play critical roles in electrical safety and system performance:

- Protection Against Electrical Shocks: Proper earthing prevents accidental contact with live electrical components from causing fatal injuries.

- Equipment Protection: Grounding helps protect electrical appliances from overvoltages and unbalanced load conditions.

- Fire Prevention: Effective earthing and grounding prevent electrical fires by safely dissipating excessive fault currents.

- Voltage Stabilization: Grounding stabilizes the system voltage, ensuring consistent power distribution and reducing fluctuations.

Prevention of Electrical Damage: By maintaining safe voltage levels, both earthing and grounding reduce the risk of component damage and extend the lifespan of electrical systems.

Best Practices for Proper Earthing and Grounding

To ensure effective earthing and grounding, the following best practices should be followed:

- Use High-Quality Conductors: Copper and galvanized iron are commonly used for their excellent conductivity and durability.

- Ensure Deep and Secure Connections: For effective dissipation of fault currents, earthing pits should be properly designed and maintained.

- Regular Maintenance Checks: Periodic inspections of earthing systems are necessary to ensure their effectiveness and detect corrosion or loose connections.

- Follow Electrical Standards and Regulations: Compliance with national and international safety standards (such as IEC, NEC, and IS codes) is essential to ensure safe electrical installations.

- Use Protective Devices: Circuit breakers and residual current devices (RCDs) should be integrated into the system for added protection.

Conclusion

Although earthing and grounding share similar objectives of safety and stability, they serve different functions within an electrical system. Earthing primarily focuses on preventing electric shocks by maintaining zero potential on exposed metal parts, while grounding ensures system stability and balances unbalanced loads. Understanding their differences and proper implementation is crucial for maintaining safe and efficient electrical systems in residential, commercial, and industrial applications.

By adhering to proper earthing and grounding practices, we can prevent electrical hazards, protect valuable equipment, and enhance the overall reliability of electrical installations.